Vynagrip protects workers from oily floors

Engineering plant Howco Whitham wanted a permanent flooring solution that would keep floors safe, plus provide employees with comfort underfoot.

The problem

Howco Whitham is a heavy engineering plant in South Yorkshire, England, and one of the area’s leading steel stockholders. The cutting fluids used in their engineering processes meant a large volume of oil, grease and grime was ending up on the production floor, creating slippery surfaces near the workbenches and machinery. In addition, employees had voiced concerns about standing for prolonged periods on the hard flooring. The company needed to find a permanent flooring solution that would not only help prevent accidents, but also provide workers with comfort underfoot.

The checklist

- Sits flush against machinery and production lines

- Provides anti-fatigue properties and comfort underfoot

- Quickly drains and dissipates spilled liquids

- Resistant to oils and chemicals

- Can be easily rolled up for daily cleaning

The solution

We worked closely with the distributor, Rubber Safety Hygiene Ltd, to find the best solution for Howco Whitham’s heavy-duty environment. After testing several options, Vynagrip was installed against and around the machinery, as well as along the full length of the steel processing lines.

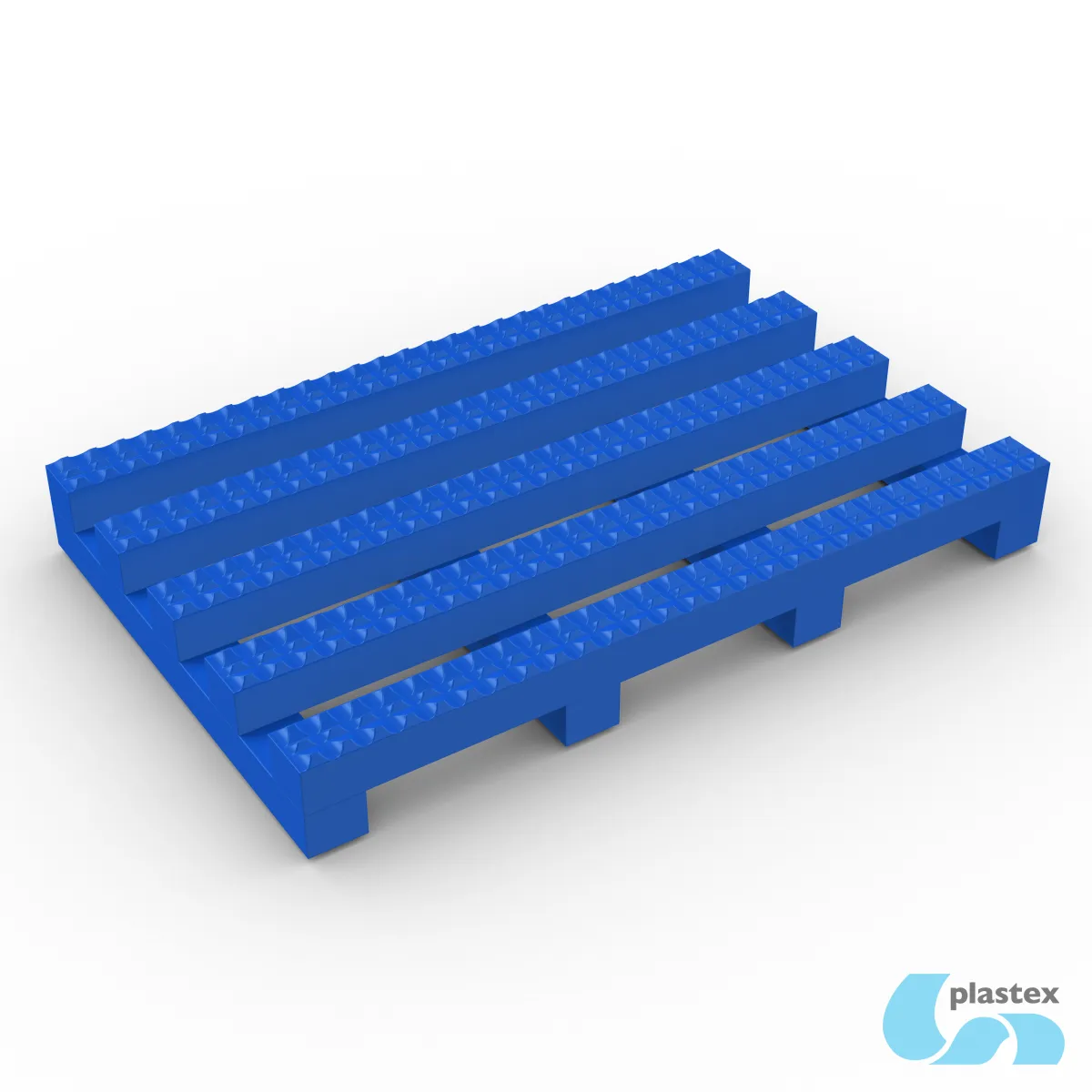

Made from non-porous PVC, Vynagrip is impermeable to oils, acids and chemicals, making it ideal for factory environments with high volumes of production waste. Its open-grid construction allows maximum drainage, while the diamond cut pattern provides superior grip and slip resistance. Vynagrip is also perfect for workplaces with standing employees: the two-layer construction provides comfortable cushioning and anti-fatigue properties proven to help boost productivity.

At a glance

Client

Howco Whitham

Brief

A permanent, slip-resistant flooring solution for a heavy-duty engineering plant

Location

South Yorkshire, UK

Environment

Industry

Product spotlight

Vynagrip

Our number one defence against slippery environments, Vynagrip is a heavy-duty mat designed to withstand all kinds of workplace liquids.

Flexible formats

Choose from modules with ramped PVC edging or rolls in standard widths and 10m lengths

Simple installation

Easy to cut on site; contours to uneven surfaces

Easy to maintain

No special cleaning tools needed; easy to clean with a high pressure hose