Crossgrip PVC keeps productivity levels high

Jaguar Land Rover needed a heavy duty matting solution to keep over 3000 shift workers on a busy production line safe from slips and free from fatigue.

The problem

In 2012, Jaguar Land Rover experienced such a surge in popularity for their Evoque and Freelander models that it decided to move their Liverpool site to a 24 hour production cycle. This meant three shifts across the day instead of two, and a 30% increase in the site workforce. This rise in foot traffic on the production line meant Jaguar Land Rover quickly needed a slip-resistant and anti-fatigue mat that could be quickly installed along the entire length of a car production line.

The checklist

- Provides a slip-resistant surface

- Creates an anti-fatigue environment for the employees

- Quickly drains and dissipates production waste quickly and efficiently

- Easy to install, with minimal disruption to the 24-hour production cycle

- Lightweight and easily rolled up for cleaning and maintenance

The solution

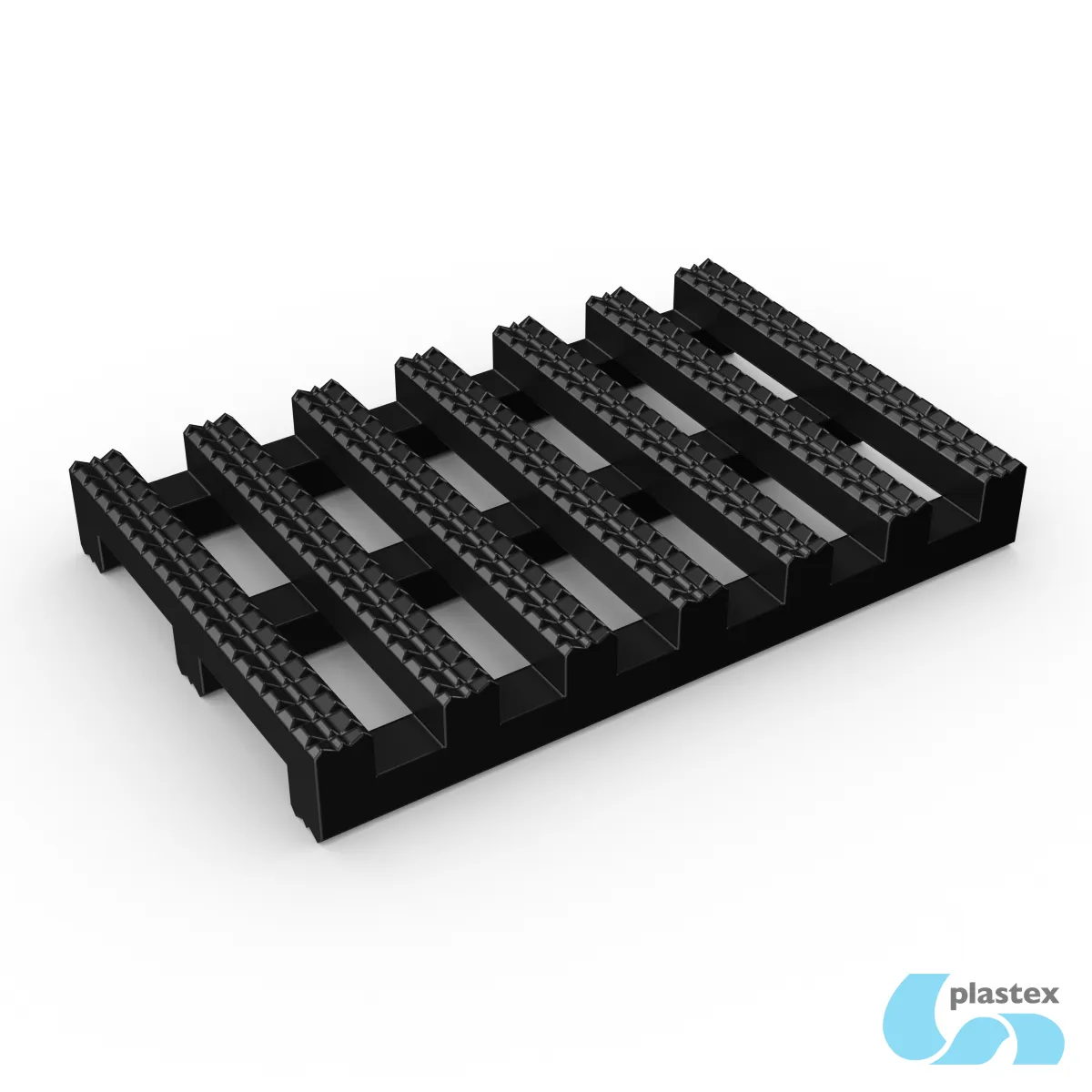

Minimal disruption to the 24 hour production cycle was of utmost importance, so it was vital that the matting be quick and easy to install. The obvious solution was Crossgrip PVC, our hardwearing walkway matting that's designed to be loose laid with no fixing required. Its one-piece construction means it can be quickly rolled out and cut to fit on site, making it perfect for the plant’s long production lines.

Made from flexible PVC, Crossgrip contours over uneven surfaces, including ramps and changes in level, while the diamond-cut pattern and cross-directional top ribs ensures a firm under foot grip. The matting's durable, two-layer construction also provides underfoot comfort for shift workers spending long hours on their feet.

At a glance

Client

Jaguar Land Rover

Brief

Heavy-duty, slip-resistant matting that could be quickly and seamlessly installed along the entire length of a car production line.

Location

Liverpool, UK

Environment

Industry

Product spotlight

Crossgrip PVC

A highly specialised walkway matting perfect for heavy-duty industrial environments, Crossgrip PVC is certified slip resistant and delivers comfort underfoot.

Flexible format

Supplied in 10m rolls

Simple installation

Loose lay, no fixing required

Easy to maintain

Five year warranty, UV resistant