Trackgrip dissipates dirt in busy transport depots

We created a custom matting solution to protect London Underground workers from the dangers of built-up of grease and grime in busy maintenance pits.

The problem

Northfields and Cockfosters are two large maintenance depots used by London Underground to maintain and service its fleet of underground trains. Here, the train engineers inspect and work on the underside of the trains, often for long periods of time. The grease, grime and water from the maintenance work had built up over time, and so the concrete floor was becoming slippery and uncomfortable. Management requested a slip resistant surface that could handle spillages and fall through, as well as mark out safe walkways for workers in the multi-layer pits.

The checklist

- Contours to the multi-layer maintenance pits

- Provides anti-fatigue properties and comfort underfoot

- Dissipates grease and grime quickly and easily

- Highly visible edging that warns workers of a difference in height levels

- Supplied in long rolls and can be installed in continuous runs

The solution

The London Underground’s engineering company JNB Construction and Engineering approached distributor Dyanwest Ltd for a suitable solution. The brief was so unique that we created a bespoke matting called Trackgrip, specifically designed to withstand greasy and grimy environments. After it was successfully trialled at the Cockfosters depot, it was rolled out to the large depot at Northfields.

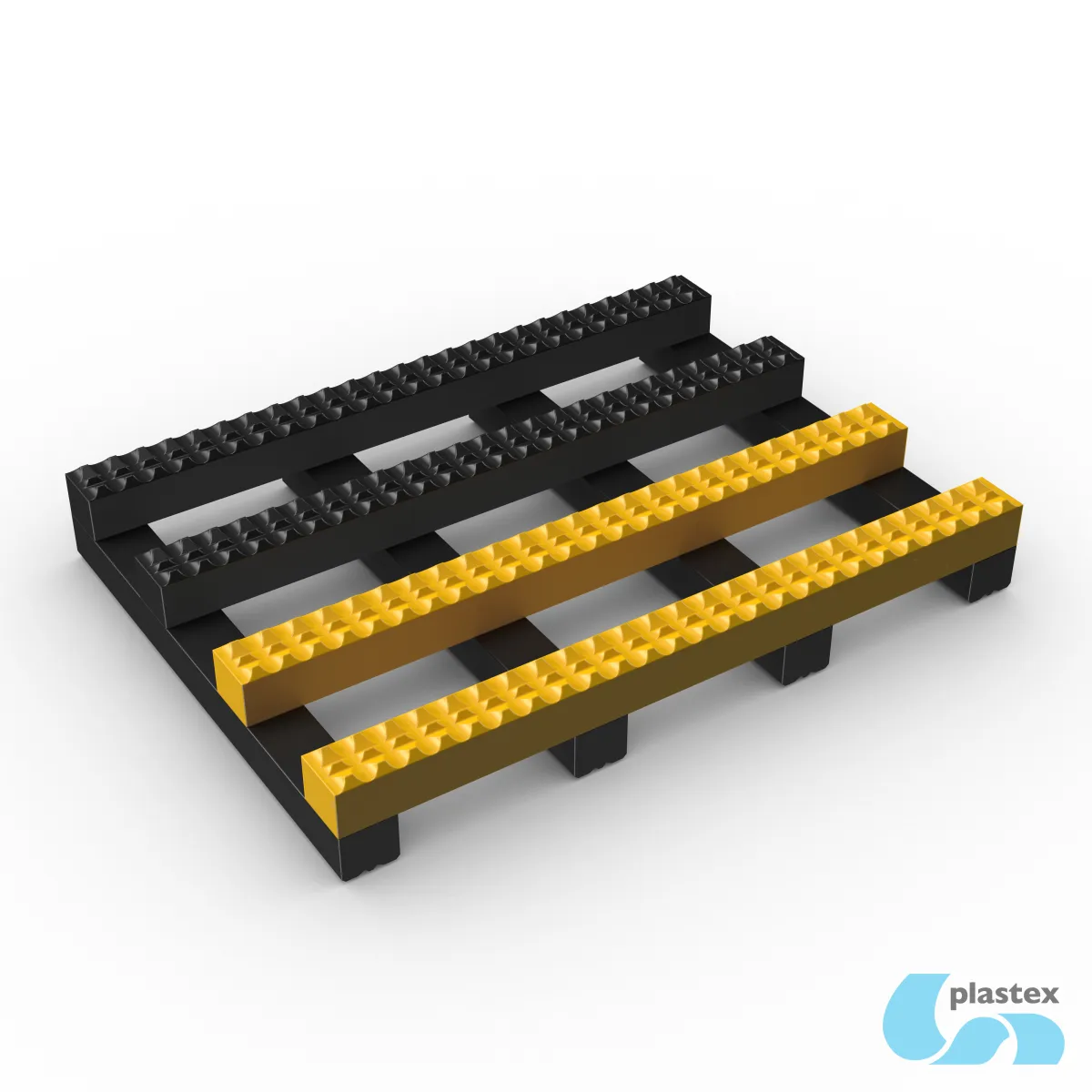

Made from non-porous PVC with a two-layer construction, Trackgrip is impermeable to fluids and provides excellent drainage. Its diamond cut pattern provides the highest slip resistance, and the wide grid means it's perfect for workplaces where oils and grease are present. The mat’s yellow edging clearly delineates where the levels change on the maintenance pit, helping to keep workers safe. Trackgrip proved to be so effective that it’s since been added to our core range.

At a glance

Client

London Underground

Brief

A heavy-duty, slip-resistant surface that can withstand grease and grime.

Location

London, UK

Environment

Industry

Product spotlight

Trackgrip

With its two-layer construction, extra-wide grid and excellent drainage, Trackgrip is the perfect defence against grease, grime and oil.

Flexible format

Comes in 10m (33') rolls

Quick installation

Roll out and cut to fit on site; contours to uneven surfaces

Simple to maintain

Easy to clean with a high pressure hose